FARET Intercooler, Unleash the Engine Power!

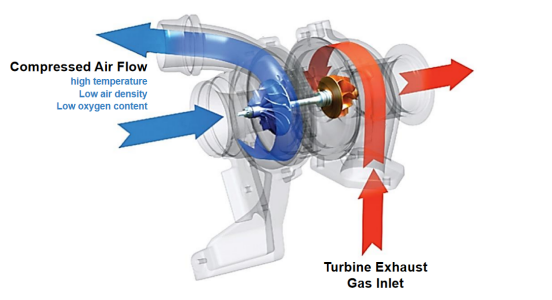

Turbocharged engines can unleash powerful performance, but the high-temperature compressed air hides hidden challenges:

1. The air density decreases

2. The oxygen concentration decreases

3. The gasoline combustion efficiency decreases

4. Increase the risk of engine knocking.

Want to break through the heat barrier and maintain stable power output? Let the POLAR intercooler help you stay "cool" under pressure!

What is an Intercooler?

An intercooler, short for charge air cooler, is a critical component in turbocharged vehicles. It cools down the high-temperature compressed air after turbocharging, reducing the engine's thermal load while increasing airintake and oxygen concentration. Thisoptimizes fuel combustion efficiency,enhances engine power output, and ensuresboth reliability and durability.

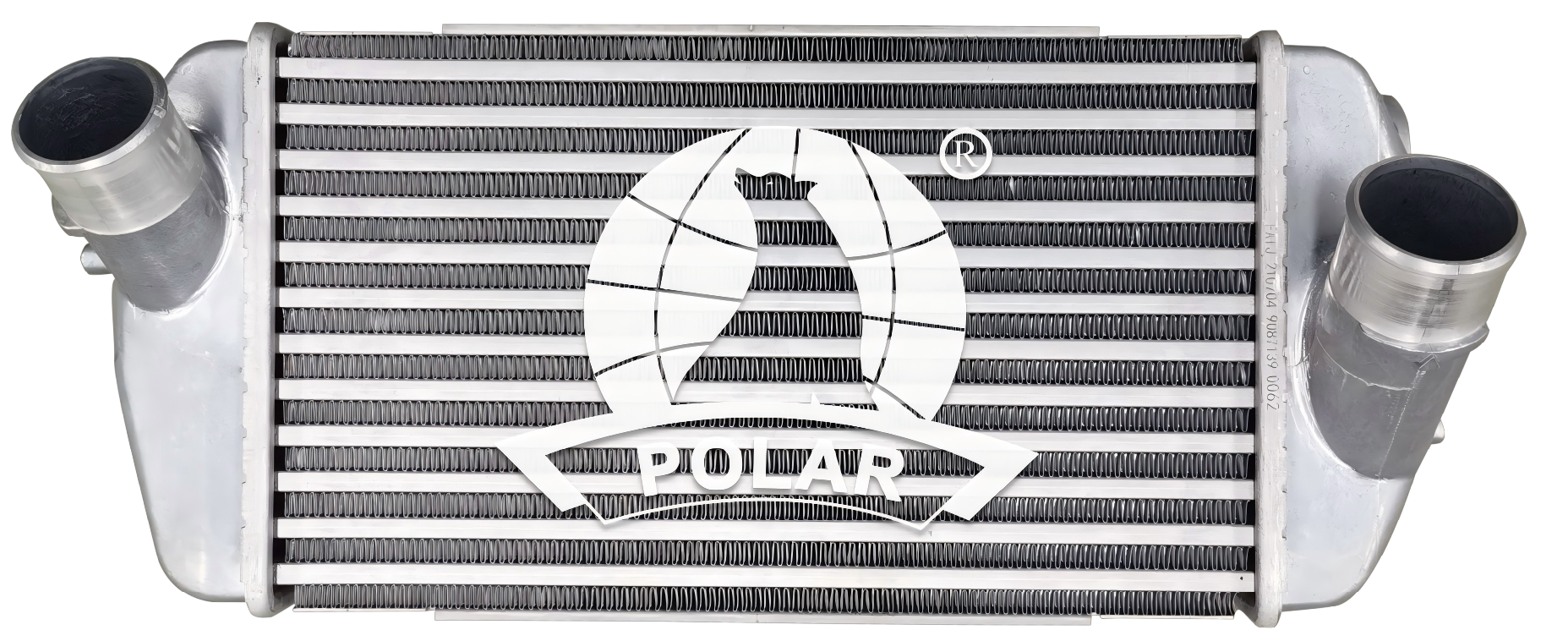

1. Air-to-Air Interccooler

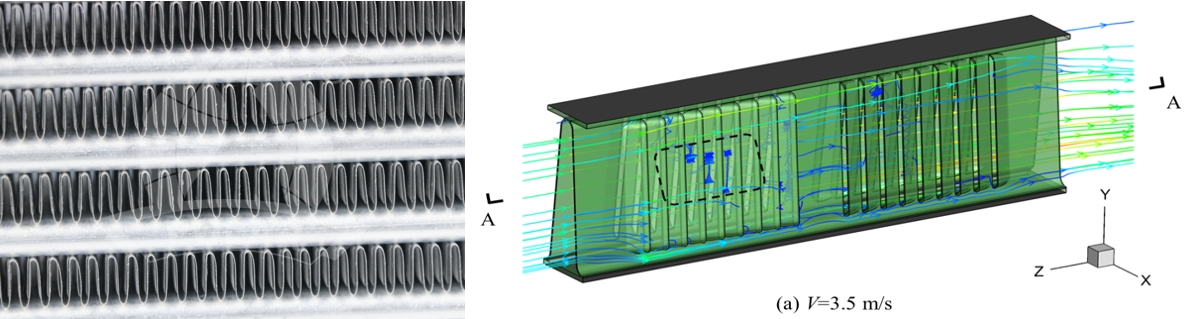

Cooling Principle: Uses air as the cooling medium. As hot compressed air flows through the intercooler, heat is dissipated via convection between the cooling fins and airflow.

Advantages: Simple, lightweight structure with superior cooling performance at high speeds, making it ideal for high-displacement, high-boost performance vehicles.

Limitations: Cooling efficiency may drop at low speeds due to insufficient airflow.

2. Air- to -Water Interccooler

Cooling Principle: Relies on coolant circulation for heat dissipation.

Advantages: Compact design with better cooling efficiency at low speeds.

Limitations: Under high-speed or sustained heavy-load conditions, rising coolant temperatures may reduce cooling effectiveness. Additionally, costs are higher.

3. Summary

Air-to-Air intercoolers suit extreme performance needs, such as racing, sports cars, and large-displacement vehicles.

Air-to-Water intercoolers are better for daily driving, offering balanced power and reliability for compact cars.

FARET Air-Cooled Intercooler: Professional Cooling, Premium Choice

1. Dual-Material Excellence | Adaptable for All Scenarios

- Aluminum-Plastic Intercooler

Features high-strength PA66-GF50/55 air tanks with 30% glass fiber reinforcement. Structural optimization in key areas enhances pressure resistance and durability.

- Full-Aluminum intercooler

Constructed entirely from high-strength aluminum-manganese alloy foil, offering superior heat resistance, anti-aging properties, and overall stability.

2. Masterful Craftsmanship | Precision Engineering

- High-Precision Manufacturing

Proprietary molds ensure accurate part dimensions, while tightly crimped end tanks prevent leaks.

- Premium Materials & Production

The plate use 4343/3003/7072 composite aluminum sheets, and fins are made from 4343/3003/ 4343 alloy. Increased tube thickness enhances burst pressure resistance.

- Efficient Cooling Design

High-frequency cooling tubes with internal fins maximize heat dissipation. Angled findesign optimizes airflow for minimal resistance and maximum cooling.

- Advanced Brazing Technology

Combines dual automated spray fluxing and suspension brazing for clean, uniform welds and long-lasting quality.

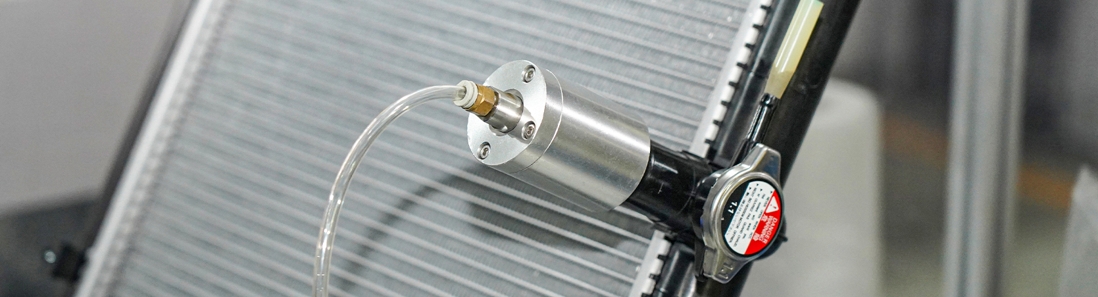

- Rigorous Testing & Secure Packaging

180 kPa leak test with zero leakage for 60 secondsSpace-saving packaging design.

About FARET

FARET has been dedicated to the automotive thermal management field for 25 years, establishing a professional benchmark with a global perspective. The company has built a comprehensive industrial chain system encompassing R&D, intelligent manufacturing, and sales. Supported by three modern production bases in Tianjin, Guangzhou, and Zhaoqing, its annual production capacity exceeds 8 million pcs. The product portfolio includes radiators, condensers, liquid cooling plates, energy storage cooling systems, and more, precisely matching 95% of mainstream vehicle models worldwide. With products exported to over 100 countries, FARET meets diverse customer needs across the globe.

Contact us NOW to get the latest quotations with discount. You would also get more market new product informations, factory visit reservation, global exhibitions and more to discover!