All You Need To Know About Oil Coolers!

On the quest for horsepower and speed, we often discuss "more powerful engines, quicker responses," yet few pay attention to how critical temperature management is behind high performance. Without an efficient cooling system, even the strongest engine can "overheat."

Among these systems, there’s a low-key but crucial component—the oil cooler. Though it may not grab attention like the engine, it plays an irreplaceable role in maintaining stable oil temperatures and enhancing overall vehicle reliability.

What Is an Oil Cooler, and What Does It Do?

An oil cooler is a heat dissipation device used to cool engine oil or transmission fluid. It facilitates heat exchange between the oil and either air or coolant, dissipating heat generated during vehicle operation to regulate oil temperature and ensure the proper functioning of mechanical components.

Lowering Oil Temperature, Stabilizing Lubrication:High temperatures reduce the viscosity of engine or transmission oil, weakening its lubricating properties and accelerating component wear. An oil cooler maintains oil temperature within the optimal range of 90–120°C, ensuring effective lubrication and stable engine/transmission performance.

Reducing Wear, Extending Lifespan:Stable, moderate temperatures mean less internal mechanical stress and slower oil degradation, extending both oil change intervals and the lifespan of the engine and transmission.

What Are the Types of Oil Coolers?

By Function,There are two common types:

1. Engine Oil Cooler

Cools lubricating oil, keeping it within the 90–120°C range to ensure proper lubrication and cleanliness of engine components.

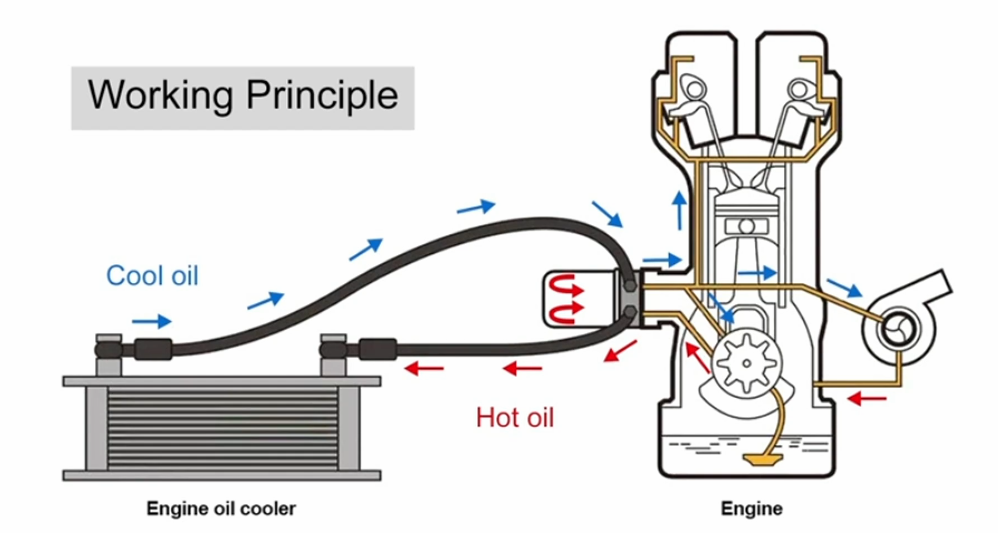

Working Principle:Operates on heat exchange—hot oil flows from the engine into the cooler, transferring heat to the coolant, which then dissipates it via the radiator. The cooled oil returns to the engine, forming a closed-loop "absorb-dissipate-return" cycle.

2. Transmission Oil Cooler

Cools automatic (AT) or CVT transmission fluid, preventing overheating and degradation to ensure smooth shifting and longevity.

Working Principle: Similar to the engine oil cooler, it exchanges heat between transmission fluid and coolant/air, dissipating heat to maintain optimal temperature.

By Cooling Method,There are two types:

1. Air-Cooled Oil Cooler:Uses oncoming airflow during driving to cool the oil, commonly found in race cars and high-load turbocharged engines.

2. Water-Cooled Oil Cooler:Compact, often mounted above the oil filter, utilizing engine coolant for cooling. During cold starts, it can absorb heat from the coolant to quickly warm the oil.

What are the symptoms of common faults in oil coolers?

Oil Mixing With Coolant:Micro-cracks inside the cooler may cause cross-leakage between oil and coolant, compromising lubrication and cooling.

Oil Leaks:Aging or damaged seals/O-rings at connections can lead to oil leakage, potentially causing low oil pressure and insufficient lubrication.

Coolant Leaks:Poor sealing in water-cooled oil coolers may result in coolant loss, leading to engine overheating, cylinder cracks, gasket failure, or even piston seizure.

Compact Structure,Efficient Cooling

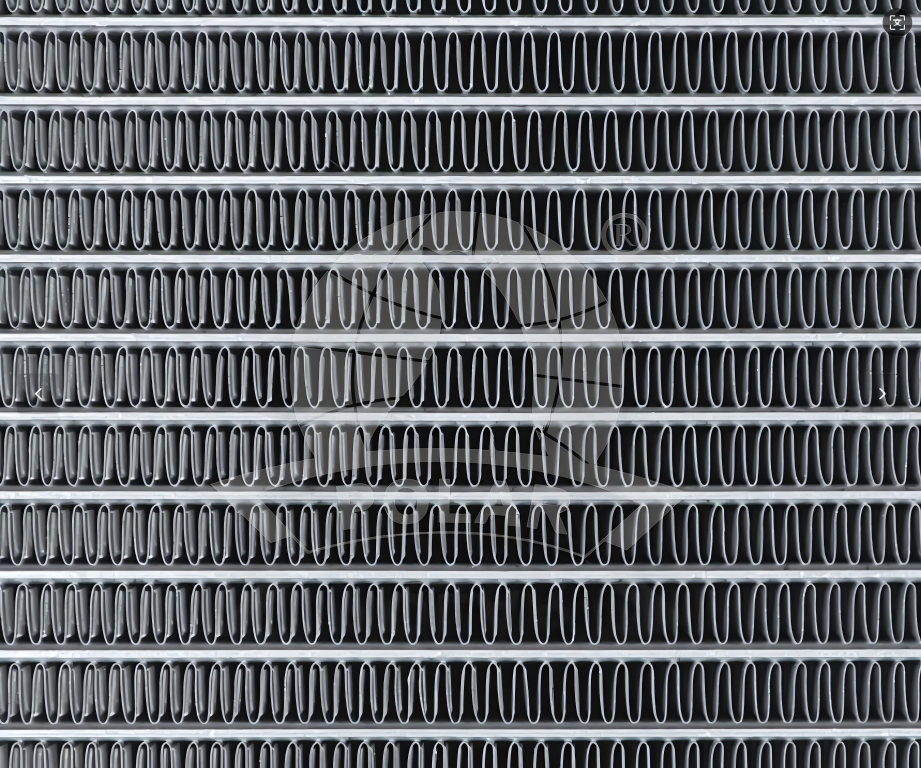

Premium Material: High-quality aluminum alloy for superior heat conductivity.

Innovative Design: Dual-side window fin design with "Wave-5" high-efficiency fin structure maximizes heat dissipation area for faster, more uniform cooling.

Rugged Durability,Premium Quality

Perfect Fit, Hassle-Free Installation

1:1 OEM-compatible standards for seamless replacement with no modifications required.

Optimized Design, Guaranteed Performance

Scientifically designed internal flow channels minimize oil resistance, ensuring consistent lubrication and preventing performance loss due to poor oil circulation.

FARET has been dedicated to the automotive thermal management field for 25 years, establishing a professional benchmark with a global perspective. The company has built a comprehensive industrial chain system encompassing R&D, intelligent manufacturing, and sales. Supported by three modern production bases in Tianjin, Guangzhou, and Zhaoqing, its annual production capacity exceeds 8 million pcs. The product portfolio includes radiators, condensers, liquid cooling plates, energy storage cooling systems, and more, precisely matching 95% of mainstream vehicle models worldwide. With products exported to over 100 countries, FARET meets diverse customer needs across the globe.