Radiator starts leaking not long after use? The problem may lie here...

In the daily use of automotive cooling systems, many users encounter a troubling issue: after only a short time, the radiator’s cooling tubes begin to suffer from pitting, leaks, or even cracks. Is this a matter of poor quality, or improper use? Today, let’s uncover the truth behind radiator tube corrosion.

1. Flat Tubes – The “Disaster Zone” of Radiator Corrosion

A radiator is made up of multiple components, including the tanks, side plates and more. Yet, in practice, the part most likely to fail first is often the flat tube. Why?

Harsh environment: Flat tubes serve as the main channels for coolant circulation. Inside, they endure constant exposure to high temperature, high humidity, and corrosive fluids. Externally, they are exposed directly to salt spray, dust, heat, and de-icing chemicals. This makes them extremely prone to corrosion.

Structural weakness: To achieve lighter weight and higher heat exchange efficiency, the walls of aluminum radiator tubes are becoming thinner, which also makes them more vulnerable.

Cost-cutting: Some manufacturers reduce material thickness and quality in order to compete for market share, sacrificing durability for lower costs.

As a result, the corrosion resistance of cooling tubes has become one of the key indicators of radiator quality.

2. The Main “Culprits” Behind Tube Corrosion

Coolant quality issues: Using poor-quality or unsuitable coolant, or even replacing coolant with plain water, leads to corrosive substances building up in the system and accelerating damage.

Material aging: Long-term exposure to high temperature or chemicals causes materials to lose toughness and develop cracks.

Electrochemical corrosion: The presence of ions in the coolant or potential differences between different metals can cause pitting or perforation of the tubes.

External environmental factors: Salt, de-icing agents, or consistently hot and humid conditions gradually corrode the tubes from the outside in.

Improper installation or maintenance: Delays in coolant replacement or damage at pipe joints can trigger corrosion risks.

Cheap products: Low-cost products often mean poor workmanship and defects, leading to compromised corrosion resistance.

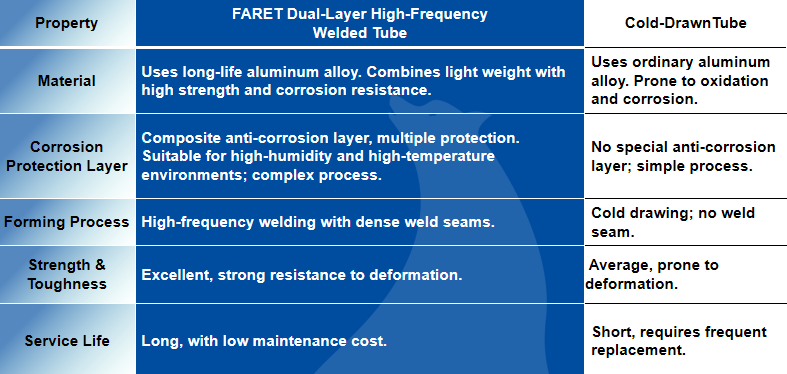

3. Cold-Drawn Tubes vs. Dual-Layer Corrosion-Resistant High-Frequency Welded Tubes

Most radiator tubes on the market are made using the cold-drawing process. While this can increase metal strength, it also carries hidden risks: If residual stress is not fully eliminated after cold drawing, stress corrosion cracking may occur, causing sudden leakage after some time in use.

In contrast, FARET adopts long-life aluminum alloys combined with dual-layer high-frequency welded tubes, offering superior corrosion resistance and structural stability—achieving both strength and protection.

4. How to Extend Radiator Lifespan

Don’t let “tap water” ruin your cooling system. Using coolant properly is the key to extending radiator life:

Use genuine coolant: Always follow the manufacturer’s specifications. Do not mix different brands, even if they are the same color. Never substitute with tap water, mineral water, or low-quality coolant.

Check and replace coolant regularly: Regular refilling and replacement not only keeps the system clean but also helps detect leaks early, preventing minor issues from becoming major failures.

Inspect pipe connections: Ensure there is no mechanical damage or looseness at the joints to prevent small cracks or leaks from accelerating corrosion.

Flush the cooling system periodically: Every few years, perform a thorough flush of the radiator. This helps remove deposits and prevents rust and corrosion.